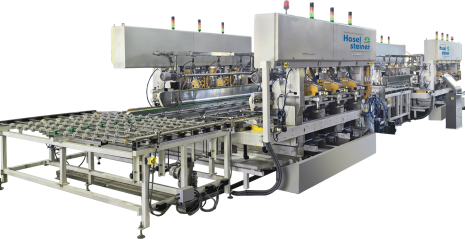

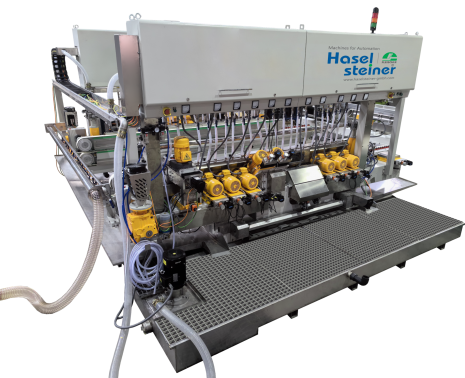

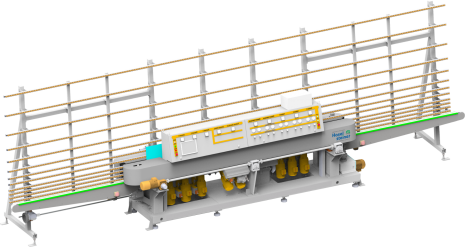

Fully automatic C-Edge grinding machine

AUTOMATIC TOOL CHANGER

This innovative tool changer system for 4 glass thicknesses enables rapid swapping of grinding wheels, minimizing manual intervention and downtime. Utilizing robotic technology, it ensures seamless transitions, precise alignment, and automatic calibration.

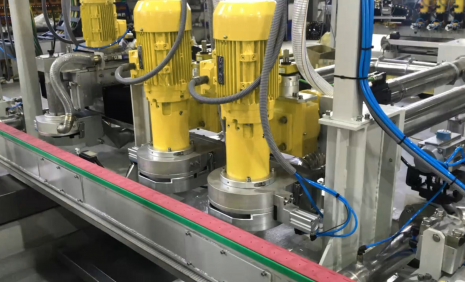

ENERGY EFFICIENT GRINDING Each fully automatic grinding machine can be equipped with 4 to 8 grinding spindles, featuring built-in polishing function and an optional corner cutting station. Powered by energy-efficient permanent magnet motors, these spindles ensure optimal performance while consuming minimal power.

CENTRAL PROCESS CONTROL

This centralized station oversees grinding processes for single or multiple lines, offering real-time monitoring of vital features and systems such as: - Glass size control with automatic adjustment of grinding parameters;

- Automatic positioning and correction function;

- Low-energy operation mode;

- Process water pressure control with automatic cleaning of the cooling pipes.