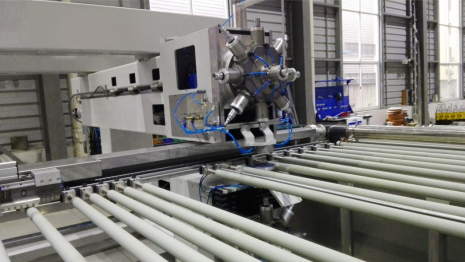

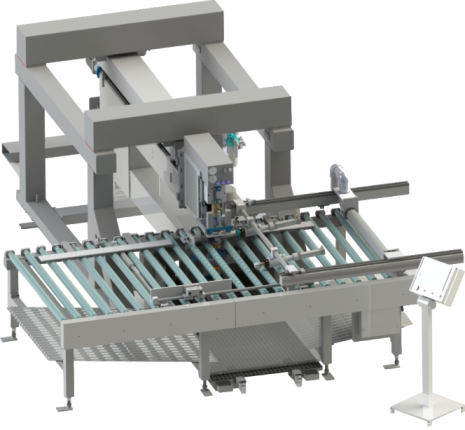

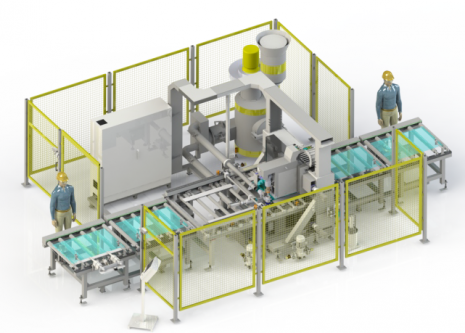

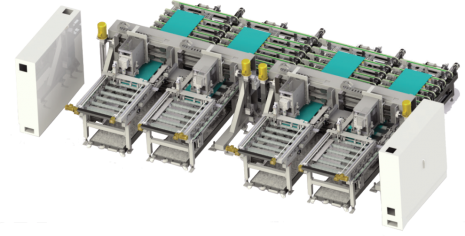

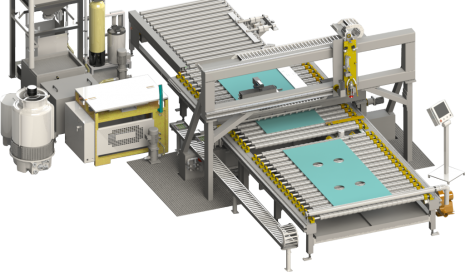

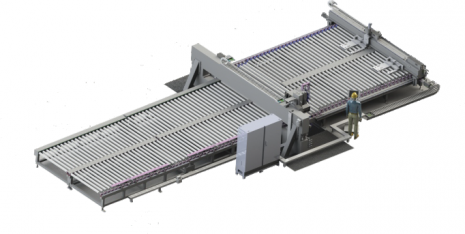

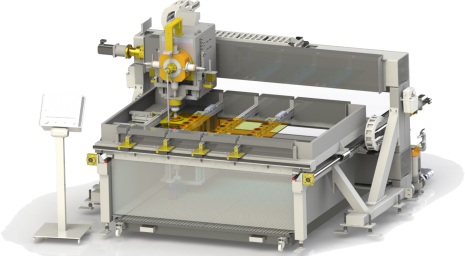

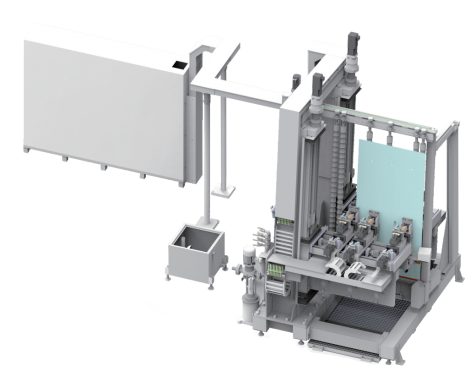

This automatic in-line drilling and milling machine is engineered for high precision and versatility in glass processing, enabling multiple operations to be performed on a single machine. It is an ideal solution for production facilities where efficient space usage is paramount. Key features of this machine include: Multi-Tool Processing Capable of accommodating up to 8 sets of drills, milling cutters, or internal grinding wheels simultaneously, allowing for diverse processing scenarious. High-Speed Servo Drilling System Imported from Germany, ensuring exceptional precision and cleanliness in drilling operations. Automatic Waste Discharge System Efficiently transfers glass waste into designated container, enhancing operational efficiency and reducing equipment failure rates and maintenance.